1. Allocate Sufficient Time in Your Project Timeline

Routine microbiology testing and Preservative Efficacy Testing (PET) are essential in ensuring product safety and quality before market launch.

However, they are often scheduled toward the end of the product development or production process, which can pose risks. If issues are revealed, it can result in delays in the product launch or even recalls if safety concerns arise.

When planning your project timeline, allocate sufficient time for micro and PET. Also, work with a cosmetic testing lab that provides timely, accurate results. This proactive approach helps mitigate risk, ensures a smooth product launch, and helps meet regulatory requirements for safety substantiation, instilling confidence in consumers regarding product quality.

Certified Laboratories recognizes the importance of timely testing and its effect on our clients' project timelines. We prioritize efficient processes and use advanced testing methodologies to provide competitive turnaround times without compromising accuracy or reliability.

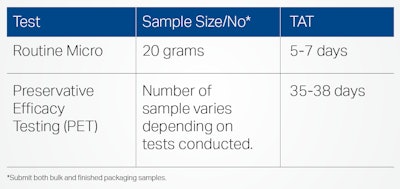

For routine microbiology testing, turnaround time is approximately 5-7 days, which is faster than other testing labs’ TATs of 7–10 days.

TAT for PET is about 35-38 days due to the 28-day incubation time, handling, testing and reporting.

2. Reserve Sufficient Sample Size

For routine microbial testing, reserve approximately 20 grams of product for testing. This amount allows for thorough testing to identify any microbial contamination accurately.

For PET, the number of samples needed varies depending on the specific tests being conducted. However, it's essential to reserve an adequate amount of both bulk product and finished packaging for micro or PET. Testing both bulk and finished packaging helps simulate real-world conditions and assess the effectiveness of preservatives in preventing microbial growth.

Additionally, testing both bulk and finished packaging reduces the risk of potential contamination, ensuring that the results accurately reflect the product's stability and safety during storage and distribution.

While some customers may choose to conduct R&D testing using only bulk samples, it's crucial to recognize that this approach may not provide a comprehensive understanding of the product's performance once it's packaged and distributed to consumers. However, for R&D routine tests, focusing on bulk samples can still provide valuable insights into product formulation and stability.

3. Conduct Sufficient Research on Alternative or Natural Preservatives

Clean beauty brands often use natural or alternative preservatives to align with their commitment to natural ingredients and sustainability. However, insufficient research on these preservatives can lead to challenges, including failed preservative efficacy tests (PET) and delays in product launches.

Natural preservatives, though appealing for their perceived safety and eco-friendliness, may not always provide adequate preservation to maintain product integrity and safety. Without thorough testing, these preservatives may fail to protect against microbial contamination, resulting in failed PET tests. These tests measure the ability of preservatives to inhibit microbial growth and ensure product safety throughout its shelf life.

Failures in PET tests can cause significant delays in product launches as brands may need to reformulate or seek alternative preservation methods. These delays impact time-to-market, increase costs and potentially damage brand reputation.

To mitigate these risks, clean beauty brands should conduct comprehensive research on natural preservatives during product development. This includes evaluating efficacy, stability and compatibility with other ingredients. Additionally, brands should communicate with raw material vendors to obtain data supporting the effectiveness of alternative preservatives. By collaborating closely with vendors and conducting robust testing, brands can ensure product safety and quality while upholding their commitment to clean and sustainable beauty practices.

Contact Certified Laboratories for fast, flexible micro and PET testing.

Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Global Cosmetic Industry takes steps to ensure that you will not confuse sponsored content with content produced by Global Cosmetic Industry and governed by its editorial policy.